Vietnam is taking a significant step toward strengthening its electric vehicle (EV) ecosystem. A Vietnamese automobile manufacturer has announced plans to establish a $130 million electric vehicle battery manufacturing plant in partnership with China’s BYD, one of the world’s largest EV and battery producers. This development highlights Vietnam’s growing ambitions in the global EV supply chain and reflects the increasing importance of localized battery production in Asia.

As EV adoption accelerates worldwide, batteries continue to be the most critical and expensive component of electric vehicles. Therefore, by investing in domestic battery manufacturing, Vietnam can reduce its dependence on global supply chains. At the same time, this move helps support local EV production. Moreover, it positions the country as a potential regional hub for clean and sustainable mobility solutions.

Why EV Battery Manufacturing Matters

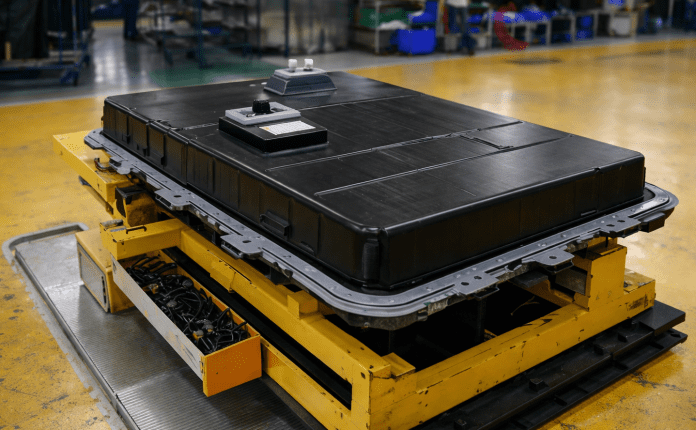

EV batteries are the backbone of electric mobility. They account for a large share of vehicle costs, determine driving range, and influence overall EV performance. Countries that succeed in building strong battery manufacturing capabilities gain a strategic advantage in the EV value chain.

For Vietnam, this project represents more than just a factory. It is a move toward:

- Strengthening domestic EV production

- Reducing reliance on imported batteries

- Supporting long-term clean energy and decarbonization goals

- Creating skilled jobs in advanced manufacturing

Key Details of the Vietnam, BYD EV Battery Project

The project involves a partnership between a Vietnamese automaker and BYD, combining local investment with global battery expertise.

Investment and Structure

- Total investment: Approximately $130 million

- Funding: Led by the Vietnamese manufacturer

- Technology partner: BYD, providing technical know-how and battery expertise

This model allows Vietnam to retain ownership and control while leveraging BYD’s proven battery technology.

Focus on Commercial EV Batteries

One of the most distinctive aspects of this project is its initial focus on commercial electric vehicles.

Instead of starting with passenger EV batteries, the plant will first manufacture batteries for:

- Electric buses

- Electric trucks

- Electric minibuses

Commercial EVs are gaining traction rapidly due to their lower operating costs, government incentives, and suitability for urban transport and logistics. By prioritizing this segment, the plant aligns with immediate market demand and public transportation electrification efforts.

Phased Production Approach

The EV battery plant will be developed in two phases, allowing gradual scaling based on demand.

1. Phase 1:

- Production capacity of around 3 GWh per year

- Focus on batteries for commercial EVs

2. Phase 2:

- Expansion to approximately 6 GWh per year

- Inclusion of batteries for electric passenger vehicles

This phased strategy reduces upfront risk while enabling long-term growth as EV adoption increases.

Why BYD Is a Strategic Partner

Additionally, BYD is recognized as a global leader in EVs and battery technology due to its vertically integrated model. As a result, by manufacturing its own batteries, power electronics, and vehicles, the company has built deep expertise across the EV value chain.

BYD’s involvement brings several advantages:

- Proven battery technology and manufacturing processes

- Experience in large-scale EV deployment

- Strong credibility in global EV markets

For Vietnam, partnering with BYD accelerates learning curves and ensures international-quality standards from the start.

Strengthening Vietnam’s EV Ecosystem

Vietnam’s EV market is expanding steadily, supported by:

- Government interest in clean mobility

- Rising fuel costs

- Urban air pollution concerns

- Growing consumer awareness of EVs

Local EV manufacturers and suppliers are increasingly investing in production capacity. A domestic EV battery plant complements these efforts by creating a more complete and resilient EV ecosystem.

This project also supports Vietnam’s broader goal of becoming a manufacturing hub for advanced technologies, including clean energy and electric mobility.

Regional Impact on Southeast Asia’s EV Market

Meanwhile, Southeast Asia is rapidly emerging as a competitive region for EV manufacturing. In particular, countries such as Thailand, Indonesia, and Malaysia are investing heavily in EV production and battery plants.

Vietnam’s $130 million EV battery project:

- Enhances regional competition in battery manufacturing

- Reduces dependence on imports from limited supply sources

- Positions Vietnam as a potential battery exporter in the future

As EV demand grows across Asia, localized battery production will be a key differentiator.

Sustainability and Clean Energy Goals

Beyond economic benefits, EV battery manufacturing supports environmental objectives. Electrification of commercial vehicles, in particular, can significantly reduce carbon emissions and urban pollution.

By enabling the production of batteries for electric buses and trucks, this plant contributes to:

- Lower greenhouse gas emissions

- Cleaner public transport systems

- Reduced reliance on fossil fuels

What This Means for the Future of EVs in Vietnam

Notably, this EV battery plant marks a turning point for Vietnam’s automotive industry. As a result, it signals a strategic shift away from traditional vehicle manufacturing toward high-value, future-ready technologies.

In the coming years, this project could:

- Encourage further foreign and domestic EV investments

- Support innovation in battery and energy storage technologies

- Strengthen Vietnam’s role in the global EV supply chain

Conclusion

The $130 million EV battery plant planned in Vietnam, in partnership with China’s BYD, is a strategic move that aligns economic growth with clean energy ambitions. By focusing initially on commercial EV batteries and adopting a phased expansion approach, the project balances immediate market needs with long-term scalability.

Ultimately, as electric vehicles continue to transform the global automotive industry, such investments position Vietnam to assume a more prominent role in the future of mobility.

I hope you find the above content helpful. For more such informative content, please visit Martecedge.